Responsible for continuous improvement of internal production efficiency. to reduce costs

Design stamping molds to reduce costs but maintain quality for customers at the same time.

Quality is assured because of precision machinery and skilled technicians.

Deliver work on time and with quality Customer satisfaction is number one.

Working Procedure

1. Bidding process

It starts with taking sample files from customers to understand and modify them so they can actually work. It can support many file formats. Then make a quotation and send it to the customer. At a price that is worth the most quality

2. Mold design process

Design, plan, and take care that product prices and production costs are not too high. To confirm the production process, which will help understand and check for problems that may occur in production.

3. Production process

Produce high quality molds in an ISO9001 standard factory using complete equipment, starting with Milling machines, CNC machines, EDM/Wire cut machines, as well as other processes that make precise molds. It is in line with the design that customers want the most.

M/L MACHINE

MACHINE IN THAILAND

ชุบแข็ง

MACHINE IN THAILAND

W/C MACHINE

MACHINE IN KOREA

MACHINE IN THAILAND

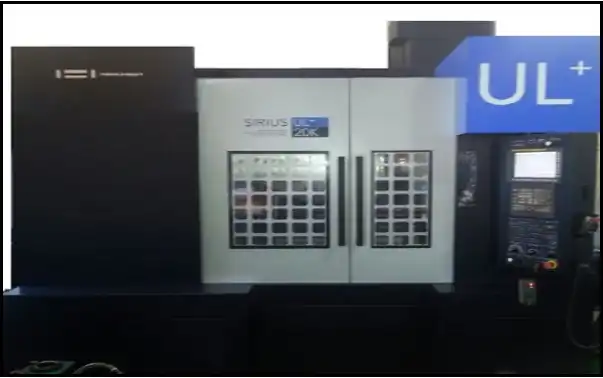

CNC MACHINE

MACHINE IN KOREA

MACHINE IN THAILAND

4. Assembly and QC

Quality check By measuring the correct size of parts before assembling. so that the mold can be used for a long time The structure is guaranteed up to 300,000 short and can be used to produce quality workpieces. In addition, the factory has a PRESS machine with sizes of 250T, 300T, so it can test the functionality of the mold and the size of the workpiece initially. In order to get the best quality before delivering to customers.